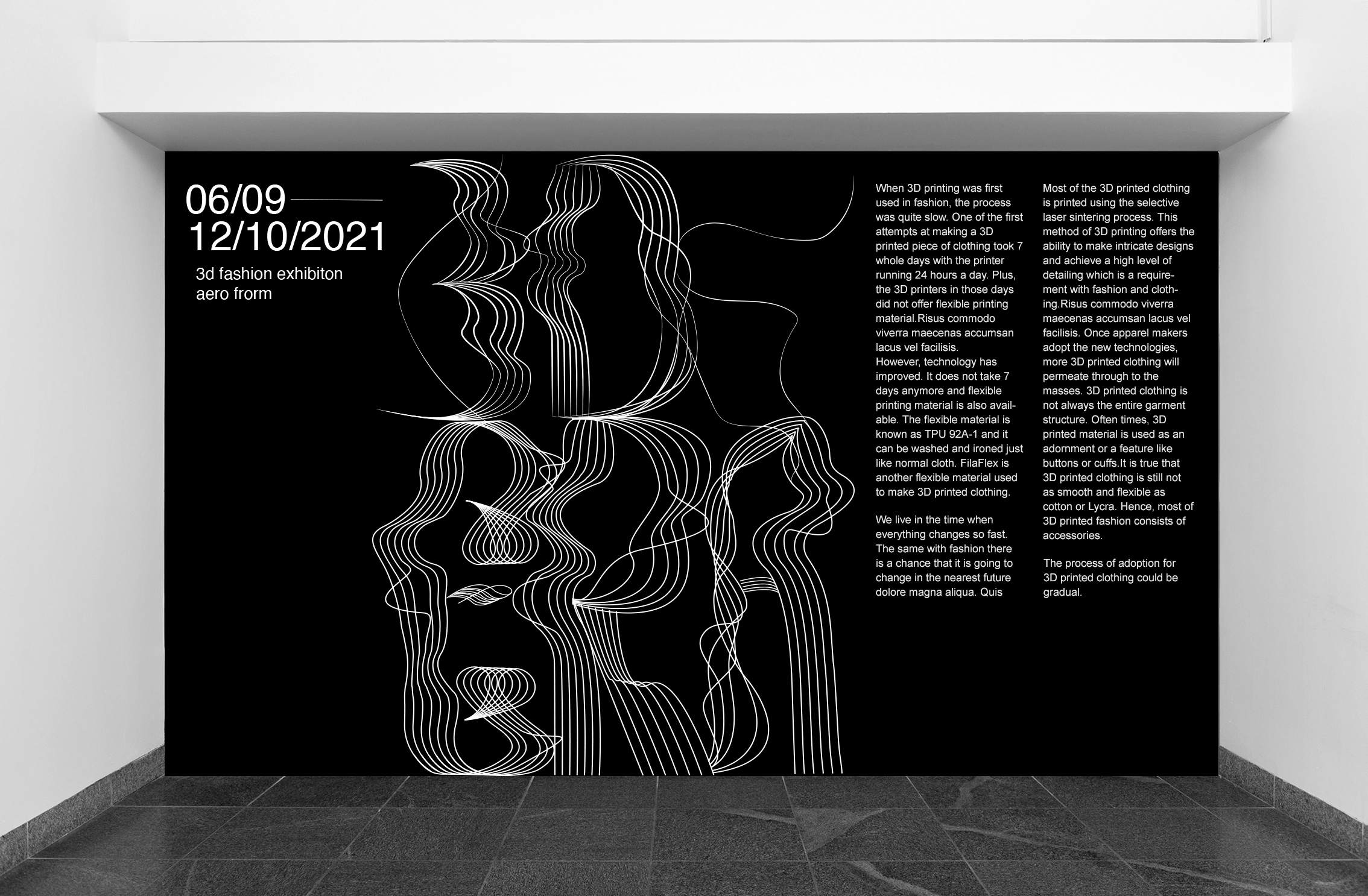

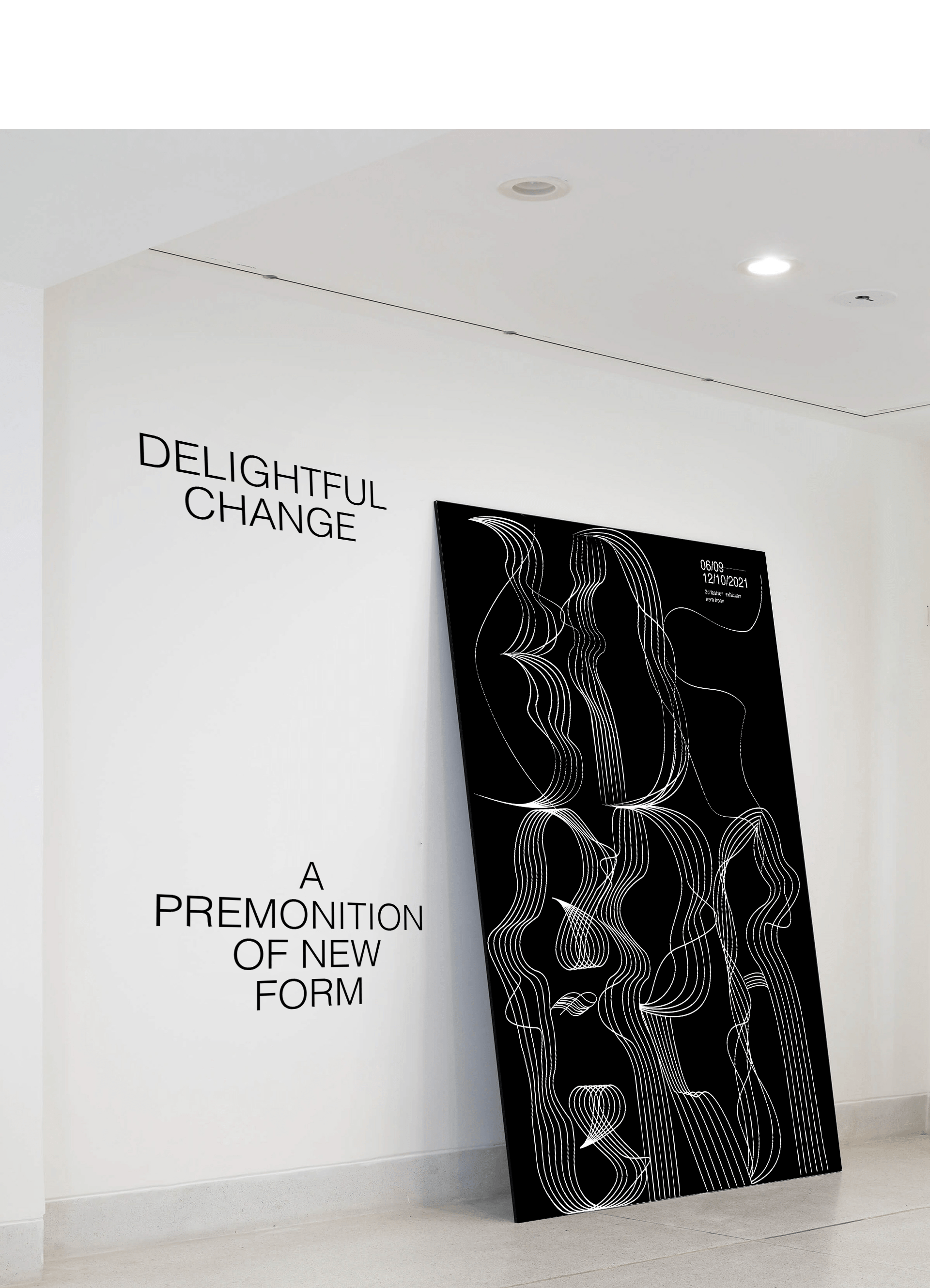

Aero Form – an exhibition about a new alternative textile production in the fashion industry. 3d printing of clothes is considered as way to reduce production costs and easy disposal of old products.

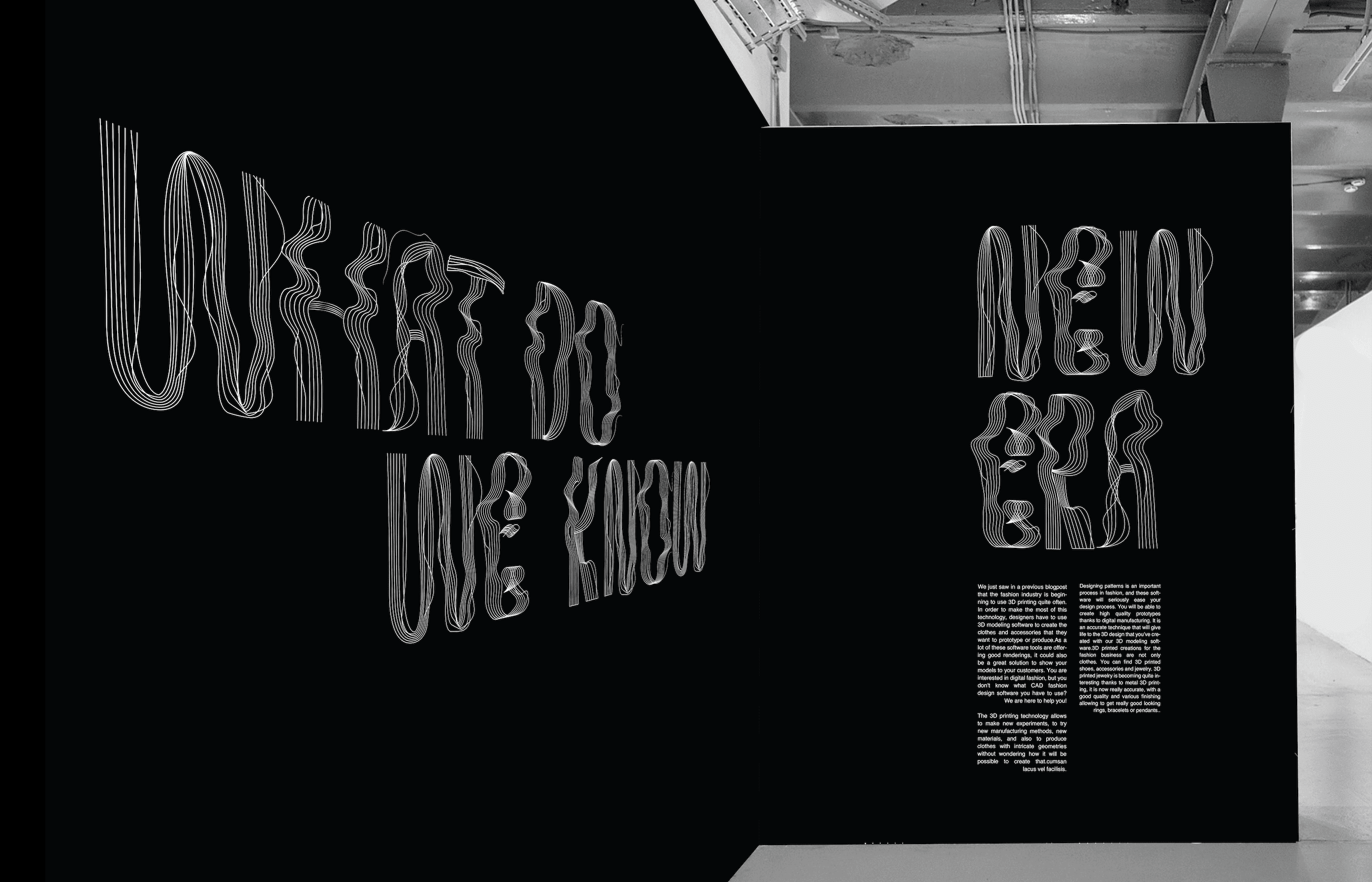

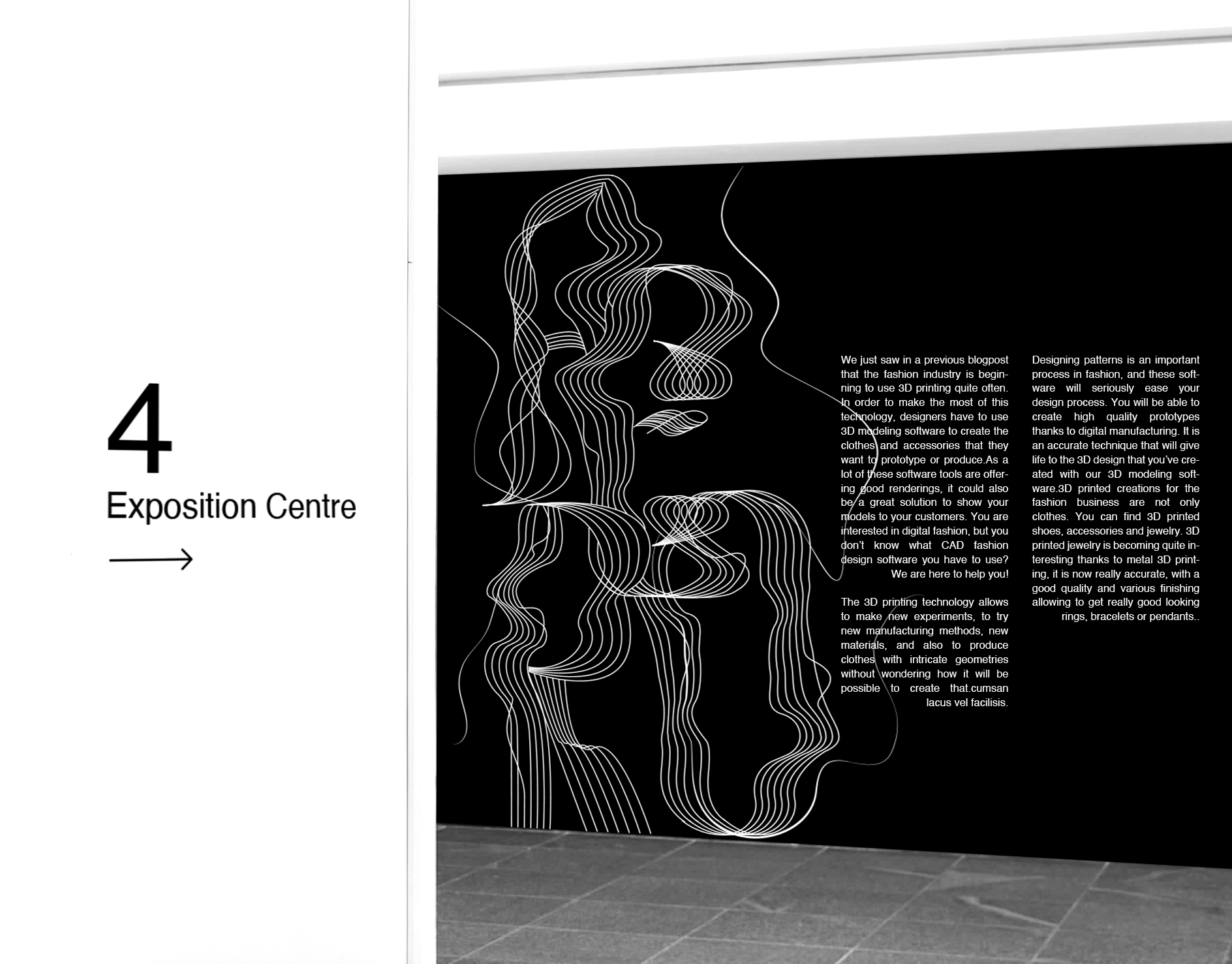

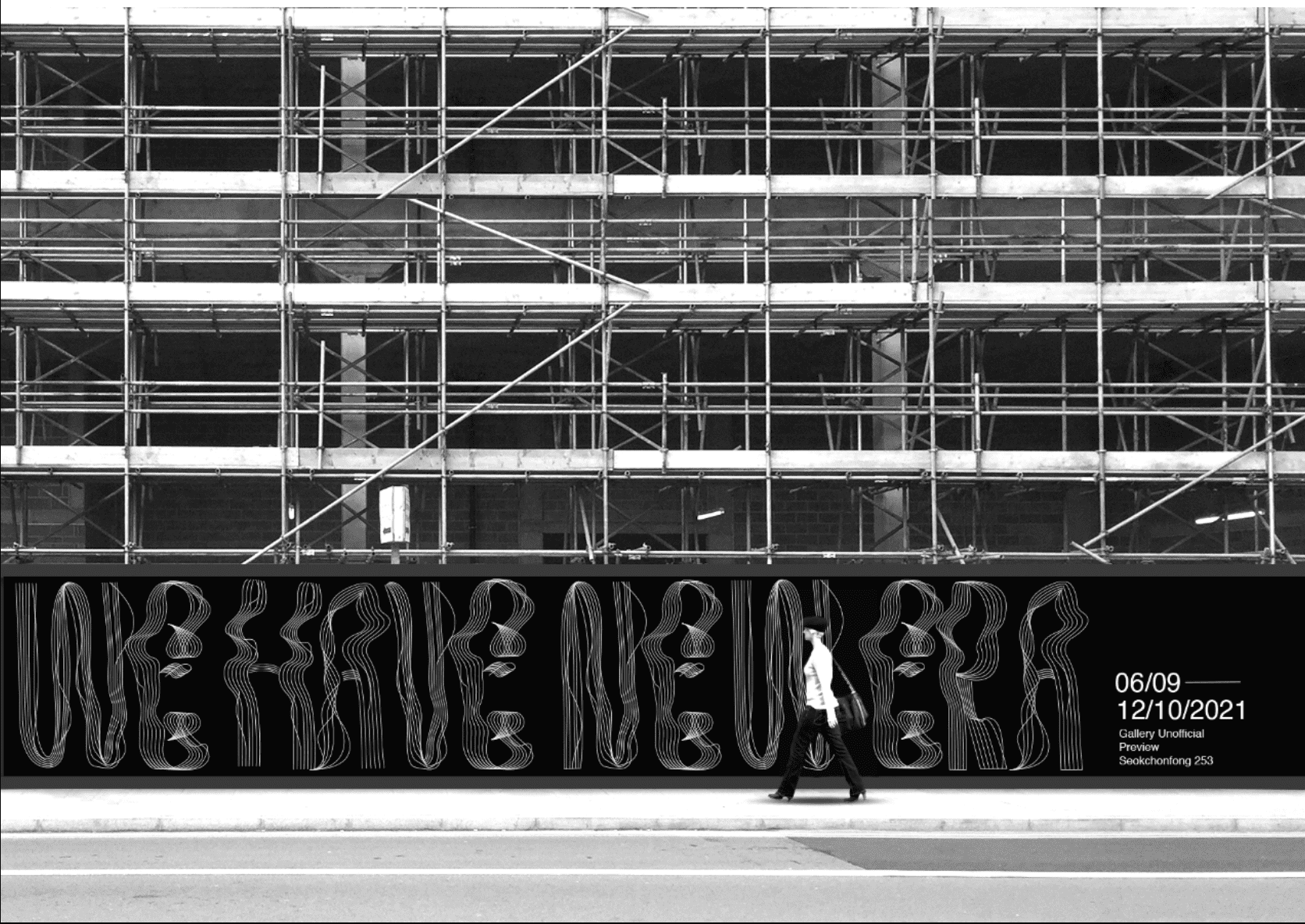

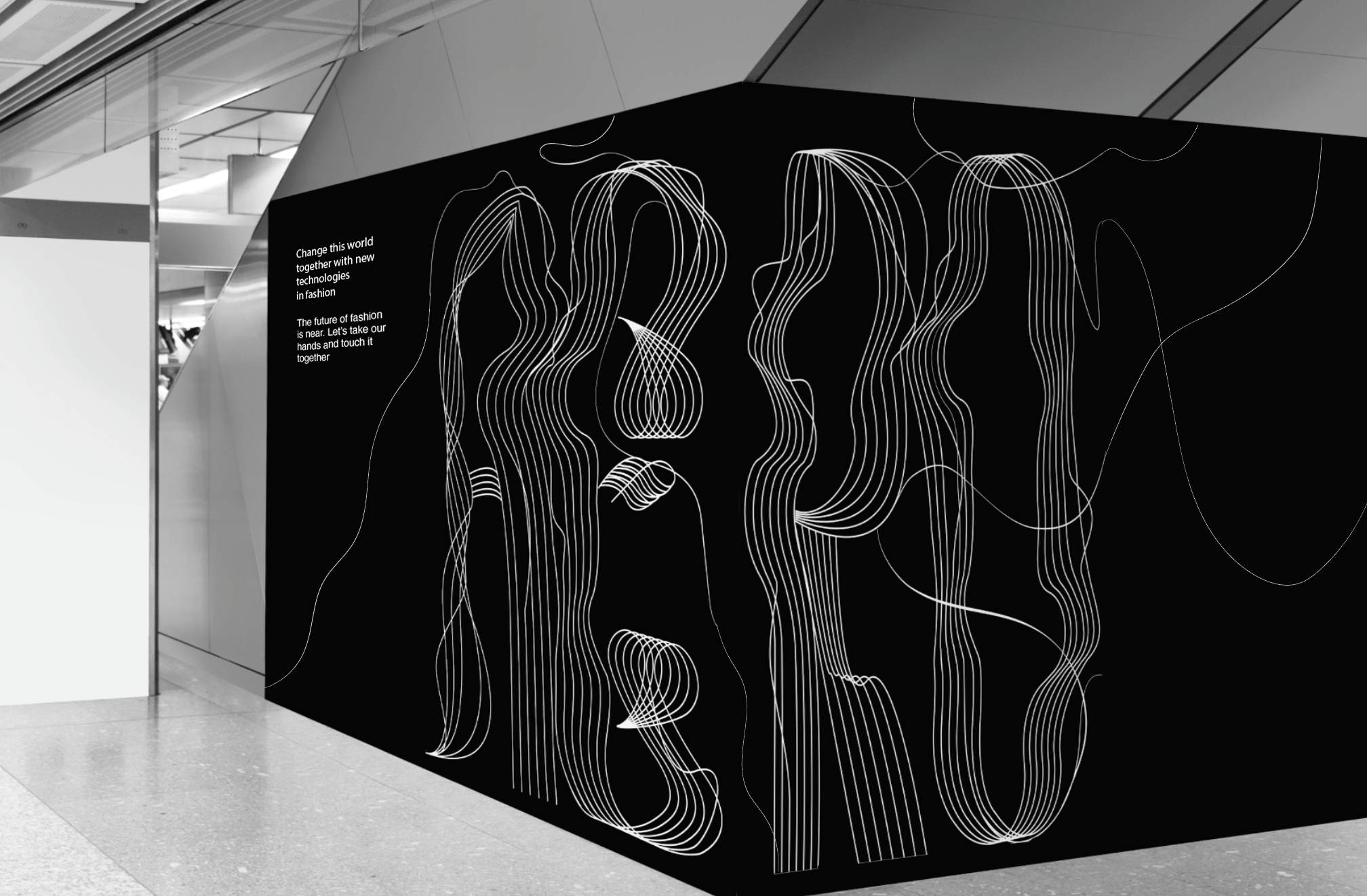

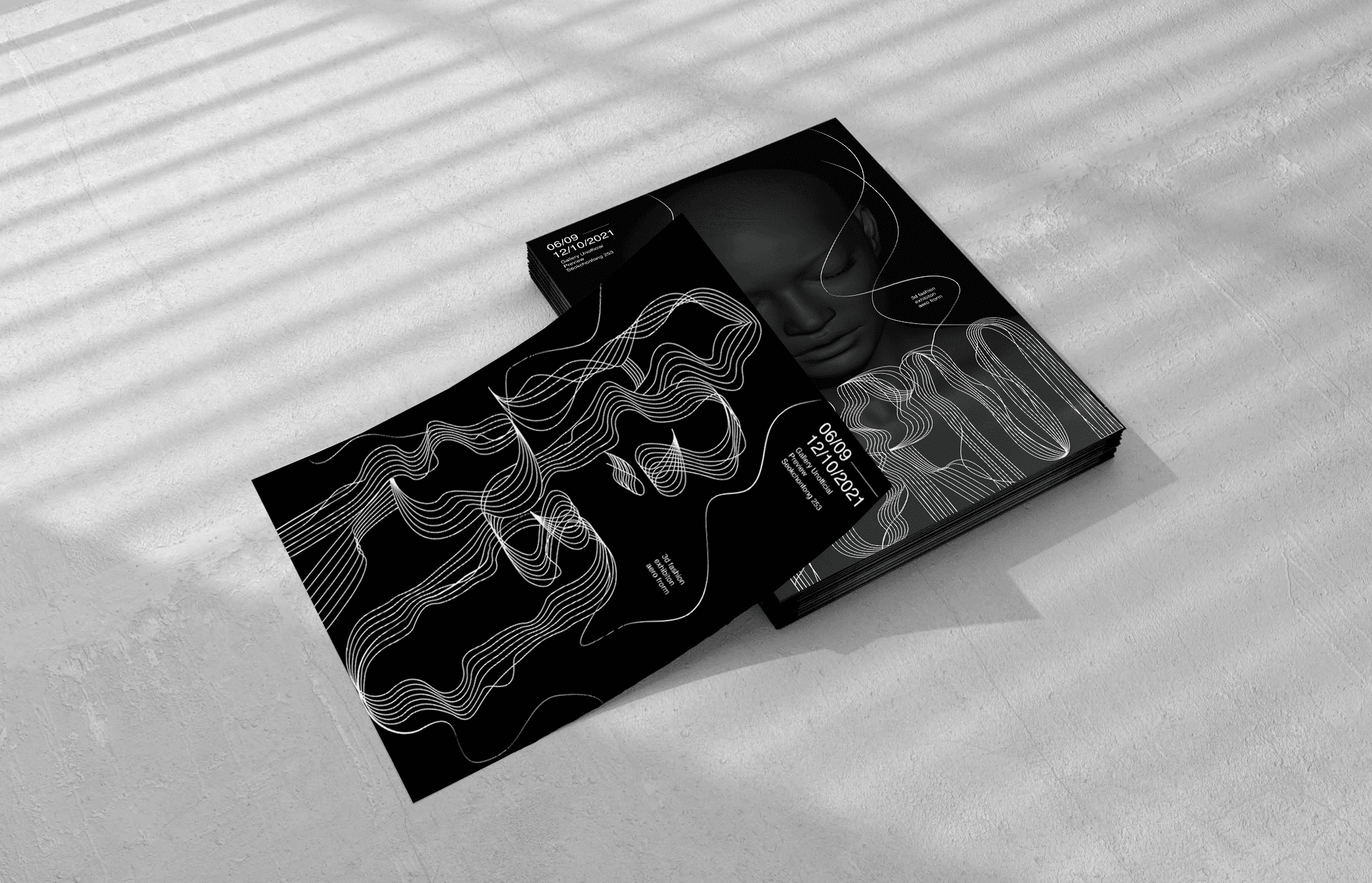

The identity is based on a display font that visually resembles to the 3d form of clothing that provides us an emotion of something new, technological and dynamic.

The long supply chain and low marginality have created another dead-end strategy of mass market fashion, overproduction. Each year, we produce 150 billion units of clothing. This would be enough to provide 20 garments to each person living on the planet. Statistics show that about 21% of all garments remain unworn or are thrown out brand new.

The majority of these garments is hard to recycle and easily salvage because chemical dyes and artificial materials are used in the process of manufacturing. But such is the economic reality of the contemporary supply chain. For the fashion corporations, the profit from overproduction (cost per item, avoiding risks from shortage, inflexible size chart) is much greater than the risks of failing to satisfy the demand. This puts a significant strain on the environment, and makes the fashion industry the world’s third largest industrial polluter after oil and gas.

Whatever computer or other innovative solutions offered by vendors and developers, the necessity of transporting the fabrics, trims and finished products invariably leads to the situation, in which the logistics, sustainability, customization, return or recycling of the purchased garment have to follow the rules of the “analog world”. This is why we believe in the future potential of digital fashion, on-demand production and, in particular, 3D printing clothes production that, with time, can become a notable sustainable tech alternative to mass production and global sourcing.

The active development, cost-cutting and market penetration of 3D printers make them one of the most promising instruments for the fast-paced development of local manufacturing. Moreover, the 3D printer design can solve the core problem of sourcing: you won’t have to search for the right fabric with the right print and qualities, as the printer will impart the necessary properties in the process of printing the fabric.

Successful resolution of this essential problem will enable the full-scale move from the analogue part of the garment manufacturing process to the digital format. It will be sufficient to send the necessary data, which we call a digital package or an improved techpack, if you will, in order to start manufacturing the garment: the digital package will contain the garment pattern, and the fabric’s qualities and design. The rest will be done by the printer.

3D printing of clothes – makes it possible to unique the approach of brands to a person, thus there will be no overproduction of clothes, since it will be printed in a style suitable for a person according to the specified parameters, exactly fit in size.

CREDIT

- Agency/Creative: Berezhna Yevheniia

- Article Title: Student Exhibition Design Concept Aero Form by Student Berezhna Yevheniia

- Organisation/Entity: Student, Published Self Promotional Design

- Project Type: Identity

- Agency/Creative Country: Russia

- Market Region: Multiple Regions

- Project Deliverables: Brand Naming, Branding, Graphic Design, Identity System, Research, Tone of Voice

- Industry: Education

- Keywords: student, hse, hsedesign, exhibition, font, fashion, identity, sustainability, 3d