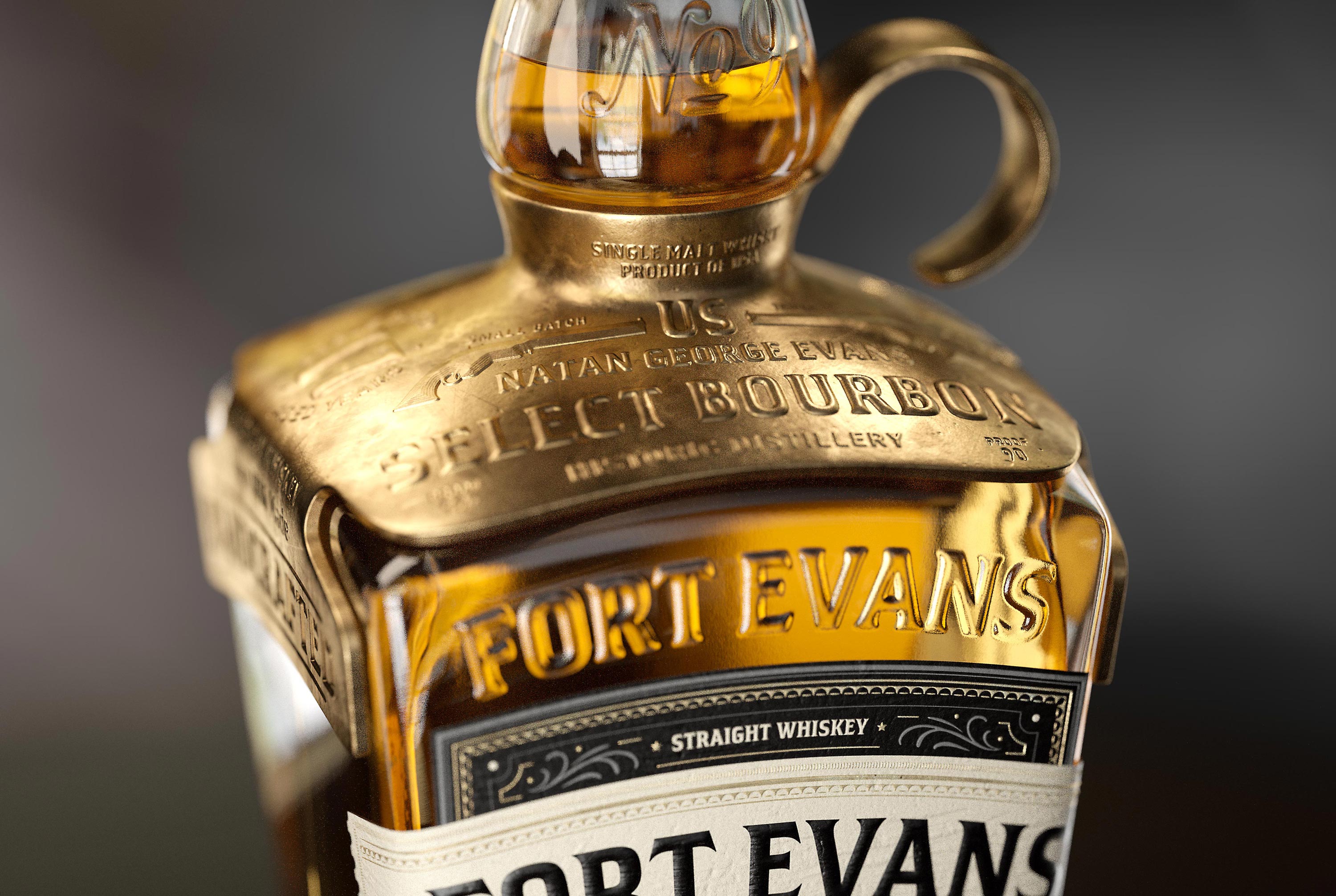

Fort Evans

This seventeen year old expression is made in the same way as its bouFort Evans Whiskey Packaging Designrbon bottled in bond counterpart, but with the addition of sugar maple charcoal filtration. It’s made using a mash bill of 70% corn, 15% rye, 15% malted barley with the corn grown on the head distiller’s farm. The whole ethos of Fort Evans is to use low distillation and barrel entry proofs to recreate a pre-Prohibition texture. The result? A wonderfully full-bodied whiskey that’s as complex as it is delicious.

Tasting note:

Nose: Milk chocolate notes arrive first, followed by plum, dark cherry, and a round, rich honey.

Palate: Consistent with the nose, with the addition of red berries, baking spices, and a sticky caramel.

Finish: The baking spices come through as the whiskey dries out.

As America took shape around the late 1700s, a large majority of immigrants with distilling knowledge arrived from Western Europe and beyond. Armed with these skills, the settlers began using European distillation techniques on New World crops and a new category of spirit was born: American whiskey.

Entrepreneurs, like George Dickel (who arrived from Germany in 1844), rejoiced when they discovered the fertile valleys of North America, favourable to spirit production. Establishing himself in Tennessee, Dickel declared it, “a distiller’s dream”, due to the native limestone shelf providing sweet, pure water and the surrounding flats yielding ample grains.

The burgeoning industry encountered its first major hurdle when, in a bid to recuperate the debt accumulated in the American Revolution, the US Government introduced a Whiskey Tax of 1791. This led to a farmer’s revolt (the Whiskey Rebellion) and caused many to relocate to tax-friendly Kentucky and Tennessee, where federal laws did not yet apply.

When Thomas Jefferson lifted the tax in 1802, the industry really grew; whiskey production flourished nearly anywhere that had good grains and water. Distilleries with access to rivers or ports had easier distribution routes and widened their customer base considerably.

Following the Civil War, the industry was recovering, and distillers were increasingly concerned with protecting their product and assuring quality, as some bonders and retailers added rogue ingredients for easier profits. To stop this, distillers lobbied congress for the Bottled in Bond Act of 1897 which established compulsory regulations for producing bourbon.

In 1920, Prohibition was passed, and all spirit production came to a halt. This marked a dark chapter in American whiskey making, with the market continuing to suffer through World War II forcing many independent distillers to close permanently.

The current resurgence of popularity for the industry was made possible by foreign demand (and investment) and the committed efforts of a select few in North America. Many of these, like Thomas E. Bulleit Jr., who inherited a fifth generation high rye content mash bill, were family members aiming to resurrect family legacies of the golden era.

A steady increase on production saw the category raise itself again and in 1964, an act of congress declared bourbon as, “America’s Native Spirit”, officially cementing its place in US culture.

Finish: The baking spices come through as the whiskey dries out.

CREDIT

- Agency/Creative: Conctantin Bolimond

- Article Title: Fort Evans Whiskey Packaging Design

- Organisation/Entity: In-House

- Project Type: Packaging

- Project Status: Published

- Agency/Creative Country: France

- Agency/Creative City: Belarus

- Market Region: Europe

- Project Deliverables: Packaging Design

- Format: Bottle

- Industry: Food/Beverage

- Keywords: Whiskey alcohol packading

-

Credits:

Art director: Constantin Bolimond